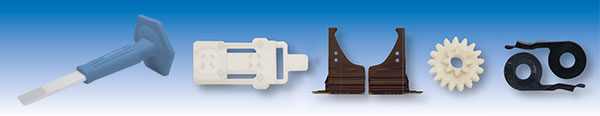

WENESIT was founded in the town of Wuppertal, Germany in 1935 and is a family business managed by its owners. Led by Heinz-Peter Beiter together with Michael Kögel, the company produces innovative and technically complex plastics items at its premises in Remscheid (Germany) and Soprón (Hungary). The company employs 30 people and operates 35 injection molding machines. For decades it has supplied many sectors and industries, from the development of parts designed for plastics through toolmaking to plastics parts production.

Quality, Humans and the Environment

As a manufacturing company we pay particular attention to the needs of the environment. We strive to put into practice the guideline of continually reducing resource consumption and climate-damaging emissions and avoiding any kind of environmental impact as far as possible. The basis of our continuing success over many years is and remains our employees. Particularly as a family business, we are aware of this fact and we treat our employees with respect and appreciation. Social responsibility, equality of opportunities, healthy working conditions, fair pay, flexibility and support for individual fulfillment are all unalterable elements of the Wenesit company culture. The cornerstones of Wenesit’s growth are quality and cooperation on the basis of partnership. We are continually investing in development, the environment, productivity and the training and development of our employees. By doing so we are promoting a continual improvement in all the processes of our company. As a result, human values and business success continue to thrive and offer security to the next generations.

History

Wenesit is a company that unites tradition and human values harmoniously with rapid progress. The company was founded in Wuppertal in 1935 by Werner Neumann. It all began with the manufacture of pressed synthetic resin parts, and the name Wenesit has been a synonym ever since for the manufacture of injection-molded technical plastics parts.

Some Milestones of Company History:

- 1935 WENESIT oHG founded by Werner Neumann in Wuppertal-Barmen

- 1971 Albert Beiter, son-in-law of the founder, becomes a co-owner of WENESIT oHG

- 1985 Michael Kögel joins the company

- 2003 Company converts to a stock company

- 2003 Heinz-Peter Beiter joins the company

- 2007 Subsidiary founded in Soprón, Hungary

- 2014 ISO TS16949 certification

- 2015 ISO 14001 certification in 4th quarter 2015

The Environmental Policy of WENESIT AG

Sustainability ensures our future business. Therefore we focus our efforts to conciliate the ecological, economical and social challenges to design and manufacture environmental friendly products.

Our environmental policy is based on the responsibility for mankind and the environment. Our contribution to the protection of the environment focuses on avoiding hazards and reducing risks.

The following guidelines are designed to be used in implementing the environmental policy in the company:

- We are constantly working at going beyond merely adhering to regulations in order to reduce environmental impacts and risks and the consumption of energy and resources.

- We take every necessary measure to prevent hazards and damage to the environment.

- Appropriate management methods ensure that our environmental policy is implemented effectively. The required technical and organizational methods to achieve this task are regularly inspected and constantly developed further.

- Each and every member of staff is tasked with acting in manner that is environmentally aware. It is an ongoing task of management to grow and promote a sense of responsibility at all levels.

- We encourage our business partners to act in accordance with our guidelines. We cooperate closely with the relevant authorities.

- We inform those members oft he public who are interested of any environmental impacts caused by the company and of our activities in relation to the environment. We provide our customers with information on how to use our products in an environmentally friendly manner.

The tasks associated with this must be seen to be an integral part of corporate policy in all parts of the company. This applies to all aspects of the company, to Purchasing just as much as to Development, Design and Manufacturing, and right up to Sales and Service.

Environmental protection and technical safety are the concern of each and every member of staff in the company. Observance of relevant legislation takes absolute priority.

One of the management´s efforts is to put in place the conditions that the safety of people and the protection of the environment are taken into account in all activities. The objective is to minimize any negative environmental impact caused by both the products and by the manufacturing methods.